富成国际

Lion Precision容积式传感器,Lion Precision涡流传感器,Lion Precision标号传感器.

Lion Precision apacitive Sensors

Lion Precision Eddy-Current Sensors

Lion Precision Label Sensors

Lion Precision Machine Metrology

Lion Precision Custom Products

Lion Precision Noncontact Displacement/Position Sensors Overview

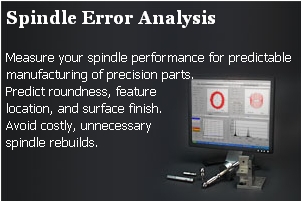

Product Families 2010 Survey Response “Lion has a good product. We have used other manufacturer's sensors but they do not perform consistently well.” Lion Precision produces some of the world's finest noncontact displacement sensors. Our product line has grown to include two technologies for basic displacement sensors and several application specific products based on our high-performance noncontact technology. To best fit your application, we also produce a significant number of custom designed sensors systems. Displacement and Position Sensor Products Capacitive Sensors Highest resolution for clean dry environments. Measurement Ranges 10 μm to 10 mm Resolution as low as 0.4 nm; Bandwidth to 15 kHz; Linearity 0.2% Conductive and nonconductive targets Eddy-Current Sensors High resolution for dirty wet environments. Measurement Ranges 0.5 mm to 15 mm Resolution as low as 0.06 μm Bandwidth to 80 kHz Linearity 0.2% Conductive targets only Compare capacitive and eddy-current sensors Application Specific Sensor Products Label Sensors The Clear Label Sensors that revolutionized the packaging industry. The overhwhelming favorite for high-tech label sensors with superior reliability and a two-year warranty Spindle Error Analysis Measure your spindle performance for predictable manufacturing of precision parts. Predict roundness, feature location, and surface finish. Avoid costly, unnecessary spindle rebuilds. Dynamic Runout Sensor High speed spindles, such as PCB and medical drills require dynamic measurement of spindle runout at operating speeds. The Targa III performs that measurement with precision and ease with Tracking TIR technology.