武田机电

TAS液压缩紧盘广泛地应用于风能领域, 在世界著名的风能设备制造商VESTAS,GE,Enercon,Nordex,Siemens,Repower,Suzlon,Gamesa, Acciona Energy都有配套使用.

TAS以其创新的技术已获得全球许多权威机构认可,通过多项认证体系认证. 认证证书-PDF TAS液压缩紧盘选型资料下载 TAS安装指南资料下载

1.TAS液压缩紧盘的安装指导

2.TAS液压缩紧盘型号系列

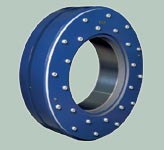

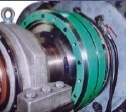

As fixing elements for friction-locked shaft / hub connections, hydraulic shrink discs have prevailed in many areas of drive technology. Today, thousands of these products are found in the drivelines of wind energy plants and also increasingly in industrial applications for the transmission of large torques. Examples and images from the field of development >> In TAS-Schafer GmbH's TAS-SHS products, the basic principle of the mechanical, three-part shrink disc has been retained. This principle has been extensively and frequently tested. Here, the power-transmitting friction surfaces are strictly separated from the hydraulic system, thus preventing these surfaces from being exposed to oil. The great advantage of the hydraulic TAS SHS shrink disc lies in the tremendous time savings during installation. This system can be tensioned at a pressure of between 120 bar and 200 bar, thus considerably reducing the installation time. This time reduction increases exponentially with the diameter of the connection. With larger diameters, e.g. 530 mm, a hydraulic shrink disc is tensed after only a few minutes. This compares to several hours' tensioning time required for a mechanical shrink disc. The hydraulic pump required for assembly may constitute a stationary unit, e.g. at test stations and assembly areas, but the use of a hydraulic hand pump is also possible. In this way, the system can also be tensioned at difficult-to-reach places. A typical application is the turret of a wind turbine. The dismantling of the TAS-SHS is also supported by the hydraulic system. The time needed, and the physical strain put on engineers and maintenance staff can thus be significantly reduced. Even after a long operating life of several years, when, depending on the site, e.g. seals no longer work, the TAS-SHS shrink disc can be removed like a mechanical shrink disc by loosening the screw connection without further pressurisation.