武田机电

UNIDOR控制器,UNIDOR传感器,UNIDOR编码器,UNIDOR测量系统,UNIDOR监视系统.

UNIDOR, the pioneer for integrated automation and press automation. We at UNIDOR are engineers – realists, for whom facts count. Our job: the automation of all kinds of presses. Our objective: to ensure operational reliability in the production of high quality manufactured parts. No one belonging to the international guild of our colleagues will claim to have ever accomplished ”one hundred per cent”. We don’t either. Yet we are very, very close, and we are proud of it. You must understand ”one hundred per cent” is not just another figure to us, it is the goal we endeavour to achieve.

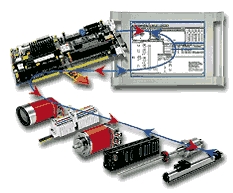

Automation <APS> <Encoder> <Sensors> <touchCONTROL> <magicTECHNOLOGY> <compactPRESS> <Measuring Systems> <PCs> APS – the integrated automated process control for monitoring interlinked systems, control and visualization of all kinds of presses. A fully integrated system that is surprisingly simple to operate. State-of-the-art technology that makes no compromises, even for the most complex of demands. more information about APS Top Sensors - Optical The right sensors for your tool - every time Optical sensors ? Digital opto sensors ? Analogue opto sensors Miniaturized single, multibeam light barriers, optical sensors and accessories for use in die integration and for other applications. All UNiDOR sensors are insensitive to oily and greasy dirt, therefore reducing time-consuming and regular cleaning to a minimum. more information about optical sensors Top Sensors - Piezo, Eddy Current, Acoustic, Ind. Piezoelectric Sensors ? Small design for use directly in the die itself. ? UNIDOR – specialists for miniaturization, for measuring accuracy in micrometers and for high stability and long life. Eddy Current Sensors ? High measuring accuracy ? Temperature stable ? Insensitive to oil mist ? Contactless measuring method ? Sturdy and compact design Acoustic Emission Sensors ? Compact ? Temperature stable ? Easy installation ( one screw only) ? High sensitive measuring ? Frequenzy range from 100kHz up to some MHz Our sensors guarantee a long and reliable operation even under the toughest conditions. more information about sensors Top magicTECHNOLOGY magicBOX, magicCONTROL, ODC .. a new wireless system for data transfer Interested ? For more information please send us an email to our export manager Mr. Andre Schuster E-Mail for more information For more information in German please click here Top Measuring Systems Optical measuring systems … ... with fast computers and complex software, the measurement of up to 3000 parts per minute is achieved. Lighting equipment and lens are of outstanding quality – enabling measuring accuracy within micrometers. In addition to fine-tuned mechanical feeding and handling equipment we also manufacture fully integrated automatic testing devices. more information about OMS Top Encoder Absolute encoder for angle and path measurements ? single turn / multi turn ? serial / parallel data transmission more information about encoders Top multiCONTROL 5 functions in one device ? Tonnage monitoring ? Double thickness sheet steel ? Analog feed measurement ? Digital die-protection ? Counter It磗 all so simple: Switch on, set up and you磖e ready to go with multiCONTROL. This modern touch display unit is extremely user-friendly, guiding its operator through any situation. multiCONTROL comes complete with accessories like sensor, connector box, charge amplifier and cables. Professional slug detection for the metal stamping industry For further information click here: Professional slug detection.pdf Manual multiCONTROL.pdf more information about multiCONTROL Double thickness sheet measurement: Eddy current sensors monitor the "generated scrap" or "slugs" in the tool or on the material BDC-measurement: Eddy current sensors are used to monitor the correct closing tool Press force monitoring: Press force between an upper and lower limit is measured Analogue feed measurement and feed monitoring: For extremly high-precision position measurement Digital tool monitoring: Up to 4 inputs (PNP/NPN). Select from dynamic , static or multiple stroke monitoring, including flank counting. Top compactPRESS The High Speed Press Control compactPRESS is a general purpose, that measures,controls,checks, compares and evaluates the analog and digital signals of sensors, encoder and transmitters. The user-friendly control with the Touch-Screen is so easy to manage and uncomplicated. Using images instead of buttons,the system guides, informs and helps through every process. compactPRESS offers an optimized function package for comprehensive tool protection and user-friendly tool management: ? min/max monitoring of all relevant tool and press parameters ? automatic tool profiling by teach-in ? long-term protection trough continual tool checks ? tool reports and tool history for economic evaluation of tool and press more information about cP compactPRESS constant press and tool monitoring and controlling We have thought of everything so that you can use the compactPRESS measuring device simply and effectively: 1. a fully-integrated system from the control through tool protection 2. a user-friendly interface that anyone can learn quickly and simply 3. universal hardware with essential components only, for a reliable and continuous operation 4. worldwide service - no matter where your press is operating, you will always have a complete control Top PC More than just a PC ? modular expansion from 1… to n PCs ? floating storage ? with DOS?WIN?/ NT?operating system ? for use in difficult, harsh environments New IPC - MIPC ? compact ? powerful ? low-cost The industrial PC for complex solutions